It's been a While

Left the Eastern Shore at the end of 2019 and moved the project to California. Long Story short, have the QB Fuse & QB Wings now.

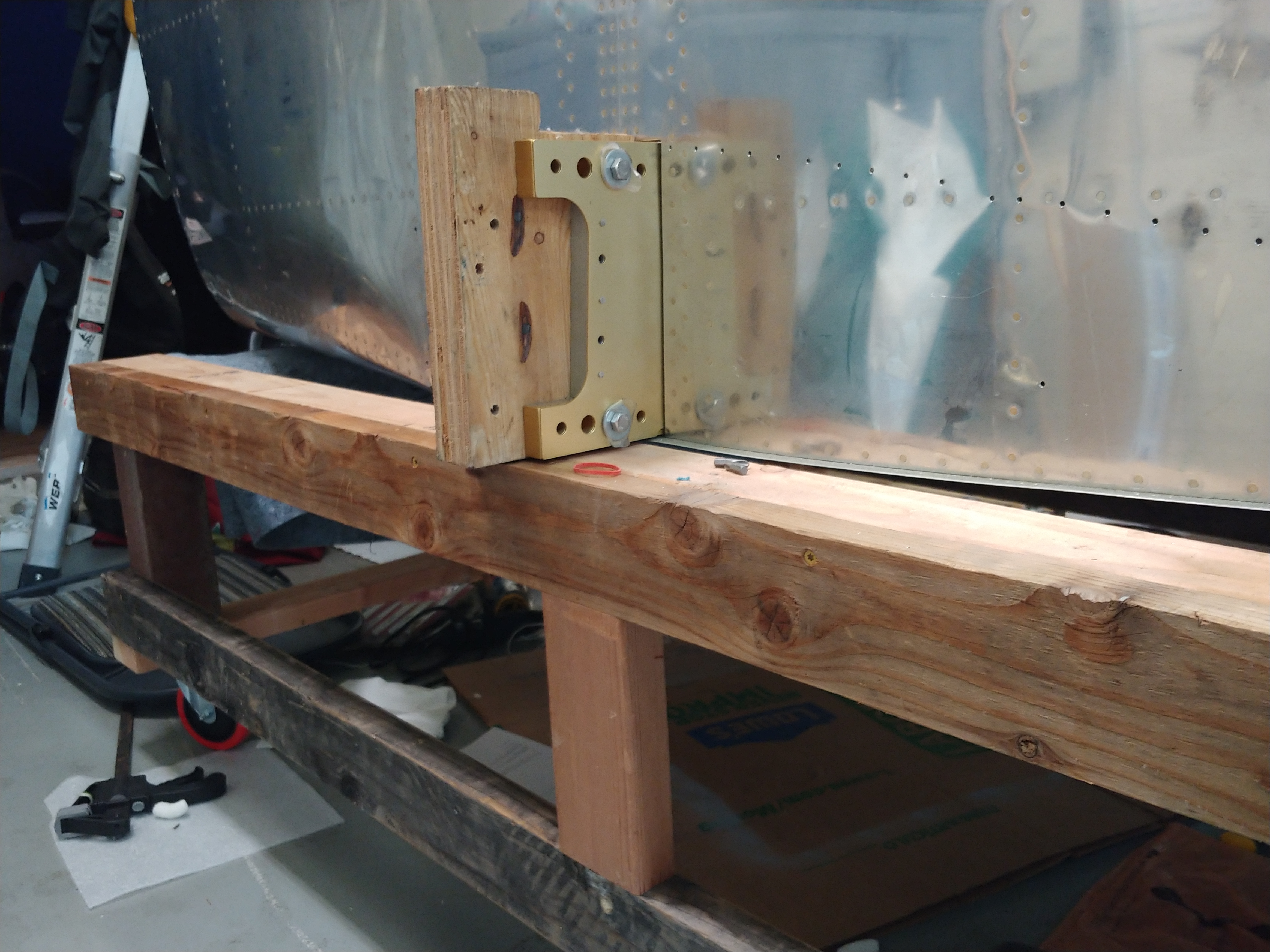

The wing cradle was built using these plans from Mouser, while the fuselage cradle was more of a design effort. It looks the most like what azcloudflyer has on his website here but we extended the stand so that the front and back of the fuse could rest comfortably on carpet while the fuselage is really held up by the spar. Put some blocks to keep the rear spar up for a level deck angle. More details of the fuselage stand [here](2020-04-09-Fuselage Stand).

Here's a quick rundown of all the work we've done in 6 months, which isn't a lot.

Tailcone

Finished up the tailcone riveting and drilled out whole lines of rivets from this area. It turns out riveting quality while solo leaves a lot to be desired especially in this area. Turned out pretty good once I had a helper. Stopped at empennage attach for now and moved on to the fuselage as I didn't want to put the VS and HS on since I'm still in a garage. This may change as I'm reading those two sections closer. I may decide to do them, and then disassemble. We'll see. Skipped to tailcone attach instead.

Baggage area

This part is basically done but had a pretty big hold up in regards to conduit. This is really the first part of my build where I had to go off plans, so it was a learning experience. I ran 4 3/4" conduits bought from Amazon, with the associated fittings, and used a unibit to punch 1 inch holes through the rear spar web. I used little plastic caps from home depot in the electrical section to cap the threads off to give it a finished look. You don't need it as the fittings come with lock washers, but it looks better. I chose this route because I figured a straight run back to the tailcone would be easier than trying to cram everything into the sidewalls. I'm still going to utilize the sidewall space by running a #2 AWG wire down the path in OP-37, and the static line down the opposite side.

Word of advice: Van's sells all the bushings and grommets you need. You can also use SteinAir and Aircraft Spruce... so I bought from all three because I kept changing my mind on what I wanted and checked Van's last.

To tie the conduit down, I used adhesive cable tie bases from Amazon. I've seen comments on VAF indicate the adhesive doesn't last long, although it seems plenty strong, so I scuffed the area where I was going to stick the base, cleaned the oils off, and stuck the bases on then used Dow 3145 RTV around the base. I think it'll hold. Any zip ties will probably do in this area but I got these milspec ones: TY25MX.

Next up...Static lines! It's so much easier to do when the tailcone hasn't been riveted....